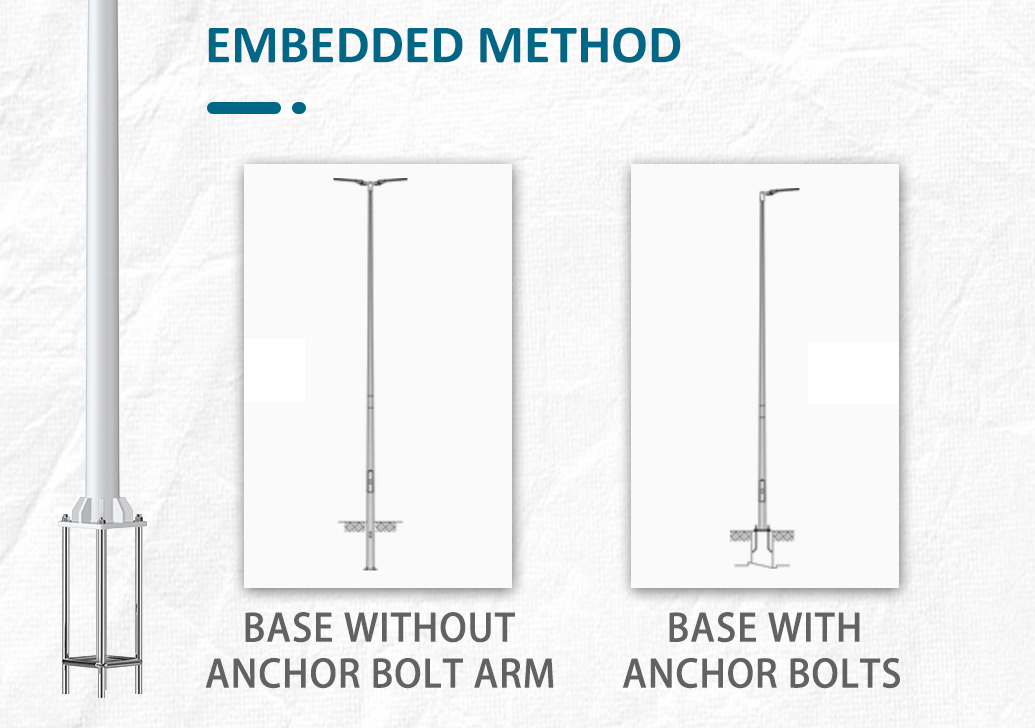

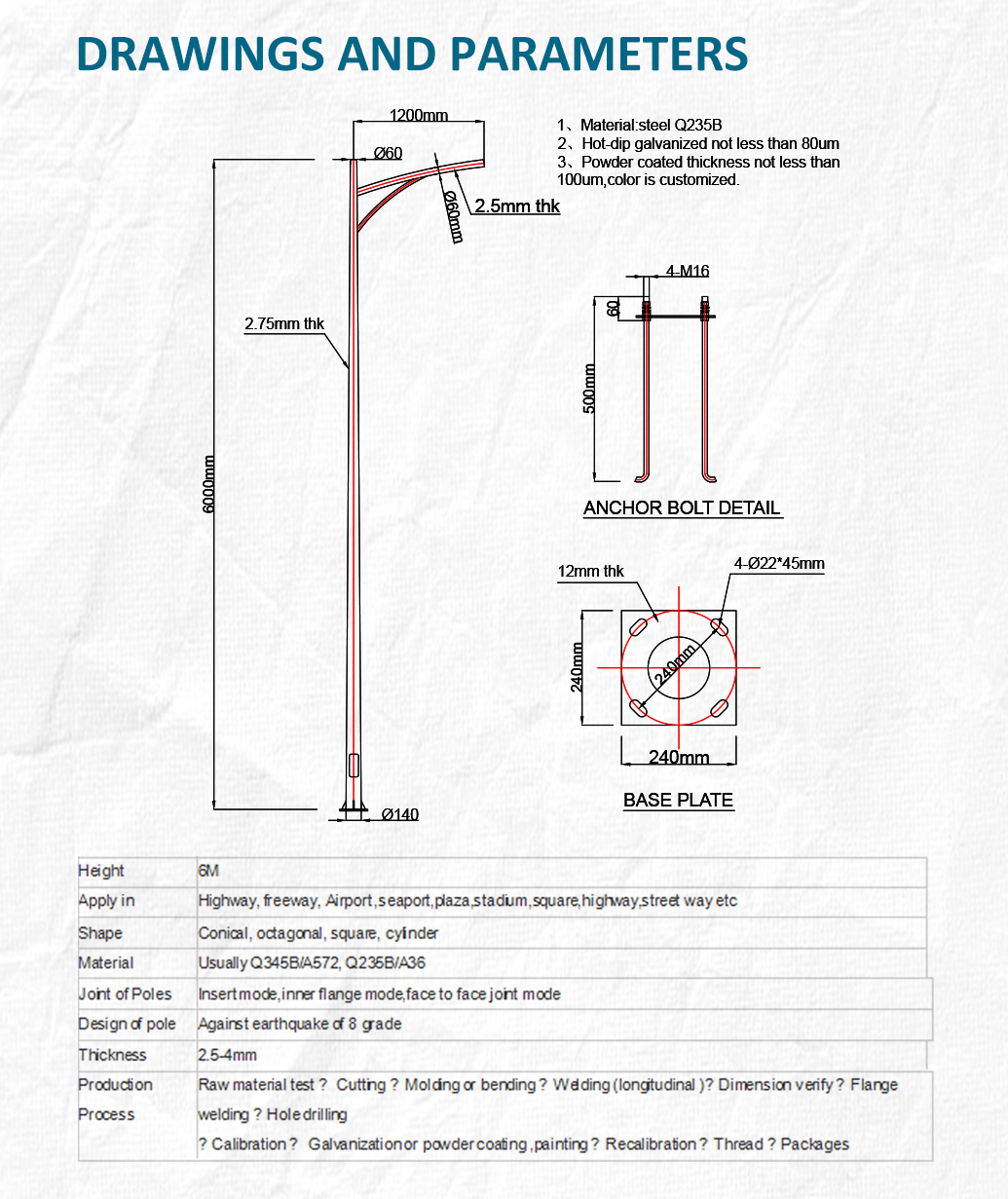

The installation methods of Steel light pole are divided into three types: direct buried type, flange type and pourable type. 1. The direct buried installation is simple. The entire light pole is directly buried in the pit, and the soil is rammed or fixed on site by concrete pouring. 2. The flange plate light pole is connected by the flange plate at the bottom of the light pole and the prefabricated reinforced concrete foundation footing bolts. The installation is very simple, and the replacement of the light pole does not need to redo the foundation. This is the most widely used installation method at present. 3. Due to the limitation of the light pole installation environment or the lack of corresponding maintenance equipment, tiltable light poles can be selected. The existing tiltable light poles mostly use mechanical and hydraulic systems, which are easy to operate and safe.1. The lamp arms (frames) of the Steel light pole are divided into single-arm, double-arm, and multi-arm types. The lamp arm is the main part for installing the illuminator. The length of the illuminator and the installation aperture of the illuminator determine the size of its aperture. The light pole and the light arm are single-handed lamps formed at one time, and the interface steel pipe with the illuminator can be welded separately. The elevation angle of the lamp arm must be calculated and determined according to the width of the road and the spacing design of the lamp induction, generally between 5° and 15°. 2. The maintenance door frame of Steel light pole generally has electrical components and cable lugs inside the light pole maintenance door. The size and height of the maintenance door frame should not only consider the strength of the light pole, but also facilitate installation and maintenance , but also consider the anti-theft function of the door lock.

The installation methods of Steel light pole are divided into three types: direct buried type, flange type and pourable type. 1. The direct buried installation is simple. The entire light pole is directly buried in the pit, and the soil is rammed or fixed on site by concrete pouring. 2. The flange plate light pole is connected by the flange plate at the bottom of the light pole and the prefabricated reinforced concrete foundation footing bolts. The installation is very simple, and the replacement of the light pole does not need to redo the foundation. This is the most widely used installation method at present. 3. Due to the limitation of the light pole installation environment or the lack of corresponding maintenance equipment, tiltable light poles can be selected. The existing tiltable light poles mostly use mechanical and hydraulic systems, which are easy to operate and safe.1. The lamp arms (frames) of the Steel light pole are divided into single-arm, double-arm, and multi-arm types. The lamp arm is the main part for installing the illuminator. The length of the illuminator and the installation aperture of the illuminator determine the size of its aperture. The light pole and the light arm are single-handed lamps formed at one time, and the interface steel pipe with the illuminator can be welded separately. The elevation angle of the lamp arm must be calculated and determined according to the width of the road and the spacing design of the lamp induction, generally between 5° and 15°. 2. The maintenance door frame of Steel light pole generally has electrical components and cable lugs inside the light pole maintenance door. The size and height of the maintenance door frame should not only consider the strength of the light pole, but also facilitate installation and maintenance , but also consider the anti-theft function of the door lock.