Double Arm Hot-dip Galvanized Light Pole

Products Details

| Product Name | Double Arm Hot-dip Galvanized Light Pole | ||||||

| Material | Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 | ||||||

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | ||||||

| Minimum yield strength | 285Mpa | ||||||

| Max ultimate tensile strength | 415Mpa | ||||||

| Anti-corrosion performance | Class II | ||||||

| Against earthquake grade | 10 | ||||||

| Color | Customized | ||||||

| Surface treatment | Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II | ||||||

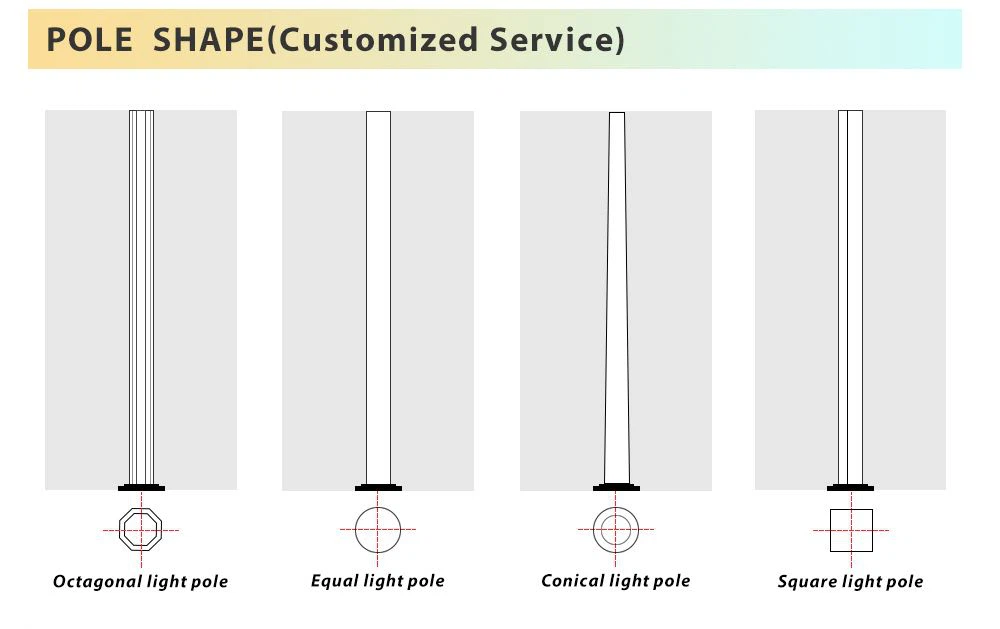

| Shape Type | Conical pole, Octagonal pole,Square pole, Diameter pole | ||||||

| Arm Type | Customized: single arm,double arms,triple arms,four arms | ||||||

| Stiffener | With big size to strength the pole to resist the wind | ||||||

| Powder coating | Thickness of powder coating>100um.Pure polyester plastic powder coating is stable, and with strong adhesion & strong ultraviolet ray resistance.Film thickness is more than 100 um and with strong adhesion. The surface is not peeling even with blade scratch (15×6 mm square). | ||||||

| Wind Resistance | According to local weather condition, General design strength of wind resistance is ≥150KM/H | ||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | ||||||

| Hot-Dip Galvanized | Thickness of hot-galvanized>80um.Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of pole is more than 25 years, and the galvanized surface is smooth and with the same color. Flake peeling hasn't been seen after maul test. | ||||||

| Anchor bolts | Optional | ||||||

| Material | Aluminium,SS304 is available | ||||||

| Passivation | Available | ||||||

Hot-dip galvanizing, also known as hot-dip galvanizing and hot-dip galvanizing, is an effective metal anti-corrosion method, which is mainly used for metal structural equipment in various industries. After the equipment has cleaned the rust, it is immersed in a zinc solution melted at about 500°C, and the zinc layer is adhered to the surface of the steel component, thereby preventing the metal from corroding. The anti-corrosion time of hot-dip galvanizing is long, and the anti-corrosion performance is mainly related to the environment in which the equipment is used. The anti-corrosion period of equipment in different environments is also different: heavy industrial areas are seriously polluted for 13 years, oceans are generally 50 years for seawater corrosion, and suburban areas are generally 13 years old. It can be as long as 104 years, and the city is generally 30 years. 1. High luminous efficiency and high light efficiency Due to the use of LED chips to emit light, the lumens of a single LED light source are high, so the luminous efficiency and luminous efficiency are higher than traditional street lamps, and it also has a great energy-saving advantage. 2. Long service life LED lamps use solid semiconductor chips to convert electrical energy into light energy and emit light. Theoretically, the service life can reach more than 5,000 hours. The double arm street light is packaged with epoxy resin, so it can withstand high-strength mechanical shock and vibration, and the overall service life will be greatly improved. improve. 3. Wider irradiation range Double arm street light has a wider irradiation range than ordinary single-arm street lights, because it has two LED street lamp heads, and the dual light sources illuminate the ground, so the irradiation range is wider.1. Different shapes The main difference between a single-arm street lamp and a double-arm street lamp is the shape. The single-arm street lamp is an arm, while the top of the pole of the double-arm street lamp has two arms, which are symmetrical, relatively speaking, compared with the single-arm street lamp. more beautiful. 2. Installation environment is different Single-arm street lights are suitable for installation on wide roads such as residential areas, rural roads, factories, and parks; while double-arm street lights are mostly used on two-way roads on main roads and some special lighting sections that require both sides of the road lighting at the same time. . 3. Cost is different Single-arm street lamp only needs to be installed with one arm and one lamp head. The installation cost is definitely lower than that of the double-arm street lamp. On both sides, it seems that the double-arm street lamp is more energy-saving and environmentally friendly in general.

Hot-dip galvanizing, also known as hot-dip galvanizing and hot-dip galvanizing, is an effective metal anti-corrosion method, which is mainly used for metal structural equipment in various industries. After the equipment has cleaned the rust, it is immersed in a zinc solution melted at about 500°C, and the zinc layer is adhered to the surface of the steel component, thereby preventing the metal from corroding. The anti-corrosion time of hot-dip galvanizing is long, and the anti-corrosion performance is mainly related to the environment in which the equipment is used. The anti-corrosion period of equipment in different environments is also different: heavy industrial areas are seriously polluted for 13 years, oceans are generally 50 years for seawater corrosion, and suburban areas are generally 13 years old. It can be as long as 104 years, and the city is generally 30 years. 1. High luminous efficiency and high light efficiency Due to the use of LED chips to emit light, the lumens of a single LED light source are high, so the luminous efficiency and luminous efficiency are higher than traditional street lamps, and it also has a great energy-saving advantage. 2. Long service life LED lamps use solid semiconductor chips to convert electrical energy into light energy and emit light. Theoretically, the service life can reach more than 5,000 hours. The double arm street light is packaged with epoxy resin, so it can withstand high-strength mechanical shock and vibration, and the overall service life will be greatly improved. improve. 3. Wider irradiation range Double arm street light has a wider irradiation range than ordinary single-arm street lights, because it has two LED street lamp heads, and the dual light sources illuminate the ground, so the irradiation range is wider.1. Different shapes The main difference between a single-arm street lamp and a double-arm street lamp is the shape. The single-arm street lamp is an arm, while the top of the pole of the double-arm street lamp has two arms, which are symmetrical, relatively speaking, compared with the single-arm street lamp. more beautiful. 2. Installation environment is different Single-arm street lights are suitable for installation on wide roads such as residential areas, rural roads, factories, and parks; while double-arm street lights are mostly used on two-way roads on main roads and some special lighting sections that require both sides of the road lighting at the same time. . 3. Cost is different Single-arm street lamp only needs to be installed with one arm and one lamp head. The installation cost is definitely lower than that of the double-arm street lamp. On both sides, it seems that the double-arm street lamp is more energy-saving and environmentally friendly in general. Featured Products

-

Garden Park Community Waterproof Road Lamp

-

High Quality Conical Octagonal Steel Highway Roadway Street Light Pole

-

30W Mini All In One Solar Street Light

-

Intelligent Led Street Light Pole with CCTV Camera

-

Factory Direct: Octagonal Signal Pole for Traffic Lights - Shop Painted Options Now!

-

LED Pathway Area Light Outdoor Landscape Light

-

7M 40W Solar Street Light With Lithium Battery

-

Park Square Outdoor Landscaping Path Light

-

TXLED-05 Economical Style Die-cast Aluminum LED Street Light

-

30W~2000W High Power IP67 Modular LED Flood Light

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours