| Height | From 15 m to 45 m |

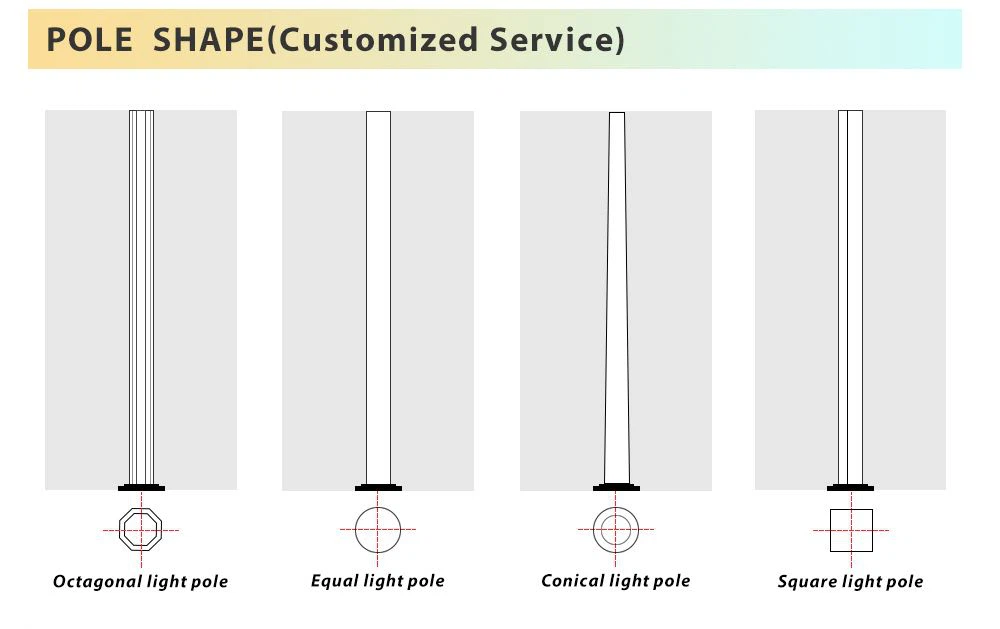

| Shape | Round conical; Octagonal tapered; Straight square; Tubular stepped;Shafts are made of steel sheet that folded into required shape and welded longitudinally by automaticarc welding machine. |

| Material | Usually Q345B/A572,minimum yield strength>=345n/mm2. Q235B/A36,minimum yield strength>=235n/mm2. As well as Hot rolled coil from Q460, ASTM573 GR65, GR50, SS400, SS490, to ST52. |

| Power | 400 W- 2000 W |

| Light Extension | Up to 30 000 m² |

| Lifting system | Automatic Lifter fixed in the inner of the pole with lifting speed of 3~5 meter per minute. Euqiped e;ectromagnetism brake and break –proof device, manual opeation applied under power cut. |

| Electric appliance control device | Electric appliance box to be be the holde of the pole ,lifting operation could be 5 meter away from the pole through wire. Time control and light control could be equipped to realize full-load lighting mode and part lighitng mode. |

| Surface treatment | Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required. |

| Design of pole | Against earthquake of 8 grade |

| Length of per section | Within 14m once forming without slip joint |

| Welding | We has past flaw testing.Internal and external double welding makes the welding beautiful in shape. Welding Standard: AWS ( American Welding Society ) D 1.1. |

| Thickness | 1 mm to 30 mm |

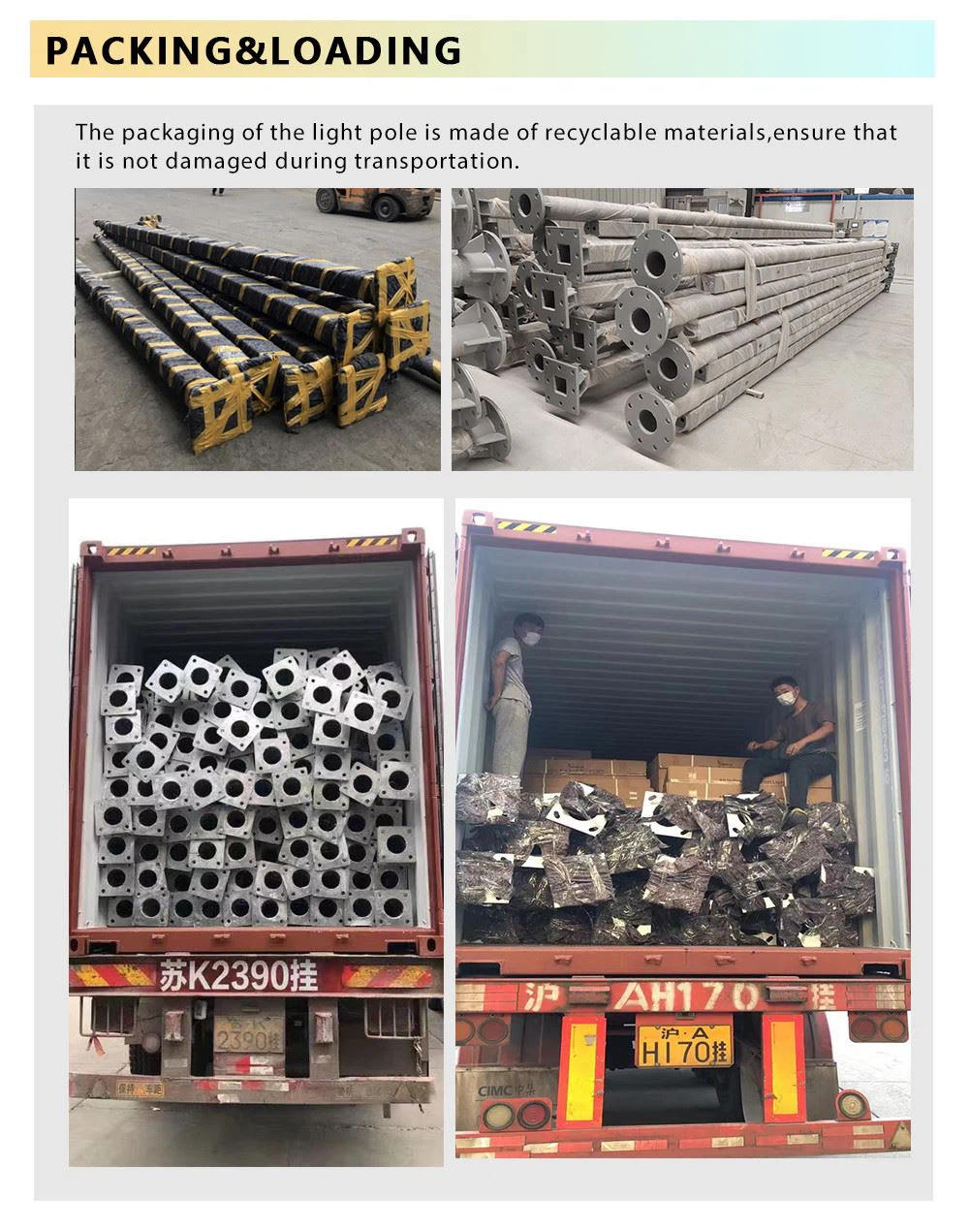

| Production Process | Rew material test → Cuttingj →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages |

| Wind resistance | Customized, according to customer's environment |

High mast light pole refers to a new type of lighting device composed of a steel column-shaped light pole with a height of 15 meters and a high-power combined light frame. It consists of lamps, internal lamps, poles and basic parts. It can complete the automatic lifting system through the motor of the electric door , easy maintenance. Lamp styles can be determined according to user requirements, surrounding environment, and lighting needs. Internal lamps are mostly composed of floodlights and floodlights. The light source is Led or high-pressure sodium lamps, with a lighting radius of 80 meters. The pole body is generally a single-body structure of a polygonal lamp pole, which is rolled with steel plates. Light poles are hot-dip galvanized and powder-coated, with a lifespan of more than 20 years, more economical with aluminum and stainless steel.

High mast light pole refers to a new type of lighting device composed of a steel column-shaped light pole with a height of 15 meters and a high-power combined light frame. It consists of lamps, internal lamps, poles and basic parts. It can complete the automatic lifting system through the motor of the electric door , easy maintenance. Lamp styles can be determined according to user requirements, surrounding environment, and lighting needs. Internal lamps are mostly composed of floodlights and floodlights. The light source is Led or high-pressure sodium lamps, with a lighting radius of 80 meters. The pole body is generally a single-body structure of a polygonal lamp pole, which is rolled with steel plates. Light poles are hot-dip galvanized and powder-coated, with a lifespan of more than 20 years, more economical with aluminum and stainless steel.